Sublimation printing is a process that creates a high quality print using specially formulated inks printed in reverse on heat transfer paper. Which are then transferred to the garment using high heat and pressure .

When Sublimation is a good choice for your Project.

Like with Screen printing Sublimation projects start with your idea. The art work is looked over or created for you by our graphic artist. You are then sent mock ups and digital proofs and once your quote is approved and paid for we move it into production. There are three types of jobs that use Sublimation at ABR Print each with a slightly varied work flow.

Small run projects

Small run projects are projects with less than 24 pieces. Items like ready made masks, images that take up less than 25% of the print area that are being added to the chest, back or sleeves of a shirt, or fun promotional gifts like mouse pads or coffee mugs. All these small run gifts and items are created right here in Bloomington. In many cases can be created the same day or within 48 hours or finalizing your order. With sublimation, unlike screen printing which needs some processing before it is ready to go to press, the print ready art that you have sent and approved can be immediately sized to fit your item. It is then printed on our sublimation printer and transferred to your shirt or small item.

Too complicated for Screen Printing

When printing entire team uniforms with individual names and numbers or wrap-around designs. ABR Print works with you to set up and finalize your artwork. But with Team uniform projects we do not print in house. Instead we spend the time making sure your art is print ready and exactly how you want it . Once it is approved and paid for it is sent to brand giant Augusta Sportswear to make your professional cut and sewn, name brand uniforms. We use a similar partner process for very large orders of other items.

Photo Realistic All-Over Designs

Designs that need to wrap completely around a garment are great candidates for cut and sew applications. We offer a few Cut and Sew items in small batches for sale. Deluxe custom masks and gators are designed, printed and assembled in house. Our all over print T-shirts are designed and printed at ABR Print then sewn locally . What you get with a cut and sewn project is a very neat and clean looking shirt, with your image covering the entire item.

Sublimation Process and Limitations

We talked a little about the process but here is a little more detail of exactly what Dye Sublimation is. Your art is printed in a one to one ratio on the transfer media . We can print as few or as many full color transfers as needed. Sublimation is the most efficient for printing small quantities of an image on white shirts or items.

Sublimation Printers

A sublimation printer is a printer that uses Specialty inks to print on heat transfer paper. Quality with a sublimation printer depends greatly on the printer that is being used. Sublimation printers can vary in price from $1,000 up to millions of dollars. At ABR Print we use a state of the art Roland sublimation printer with eight-color printhead to produce images on sublimation transfer paper. The eight colors allows us to print extremely rich and detailed prints that transfer beautifully to 100% polyester white garments, and items.

Heat Transfer Process

Once your images are printed we pre heat your garment or fabric. The sublimation paper is then placed into a heat press with the material and exposed to high temperatures of about 350 to 400 degrees Fahrenheit under high and consistent pressure for an extended period of time. This is when the ink on the transfer material turns from solid to gas. Once the ink is in a gaseous state, it will permeate the fibers of the material. When the heat is removed from the transfer paper and substrate, the ink that has permeated the fibers solidifies and is locked permanently into place. This transfer process takes approximately three to five minutes per side for set up, taping, preheating and transfer.

Some things to consider with Sublimation Prints.

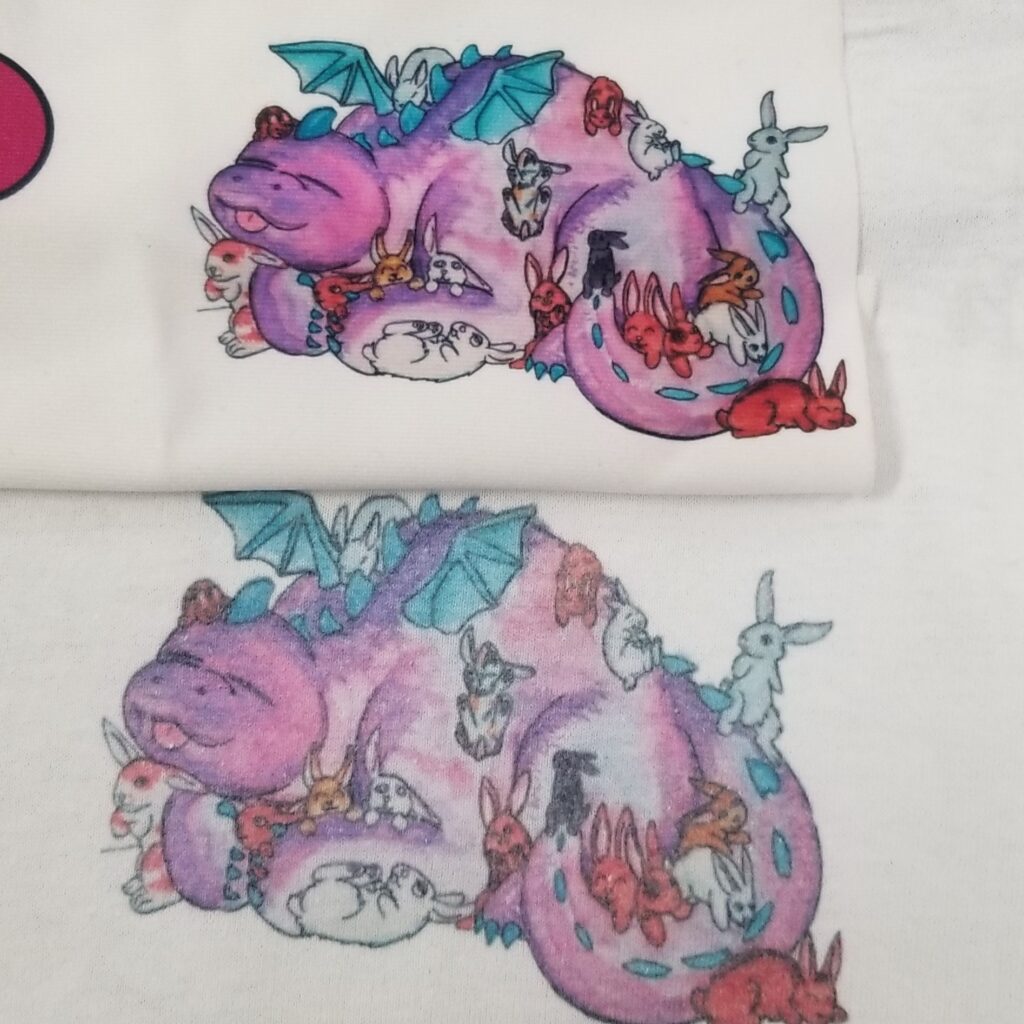

This process works best on a white, high Polyester content materials. The images to the left show an example of the print quality on a 100% polyester fabric vs a 50% cotton fabric. The image on the top is printed and transferred to a full polyester fabric and as you can see the ink was able to fully saturate and fuse with the material giving a bright rich look to the print. The image on the bottom is printed on a 50/50, poly/cotton T-shirt. As you can see it is much more faded because there’s less material for the ink to saturate and fuse to.

Translucent Ink

Sublimation ink is translucent and will look muddy or not show up well or at all on colored and dark shirts. White shirts will show the best color transfer. Their are some tricks to working with prints on light colored shirts. The example to the right is a sublimated print on a light yellow shirt. The color of the shirt bleeds through and gives the shirt a yellow ting. In order to counteract this I desaturated the yellows slightly before printing to compensate for the shirt color. The color of the base the ink sits on will determine if the images will POP! or not.

Process Time.

Small orders less than 24 garments are printed in-house. Sublimation allows a more customizable printing process. The setup is faster than screen printing, single items have a quick turnaround time. But it is much slower to print high volumes because Dye Sublimation uses different resources and processes. In contrast once a screen press is set up, each shirt can be churned out in as little as 2 minutes. Dye sublimation can take 10-15 minutes of time per shirt, if you include the time to print the transfer even longer. The base cost will be higher on Dye Sublimation Items because of the amount of handling time for each item for larger jobs. For this reason we partner with brand giant Augusta Sport for team uniforms.

Benefits of using dye Sublimation

On small orders, speed, and on large team orders a unique and fully customized item that fully represents you, your business or your team ! You get one on one design consultation by working with us. We want to make sure your design is exactly how you want it for cut and sew garments. One on one consultation and design is done with all Dye Sublimated items. The cut and sew process is very size and pattern specific.

More detailed posts on the dye sublimation process and some neat effects we can get combining Dye Sublimation on top of Vinyl will be posted in the future, so keep a look out for updates!